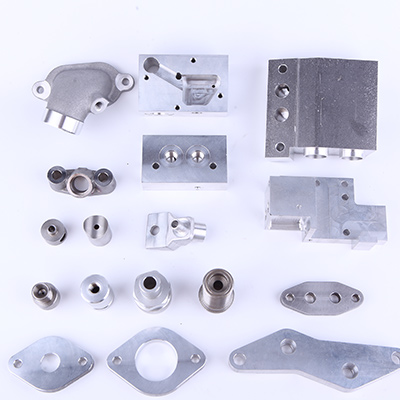

Customized Precision CNC Machining Parts

Similar products

Precision Hot Forging Flanges with Stainless Steel

The processing quality is stable, the machining accuracy is high, the repetition precision is high, the processing requirement of the aircraft is suitable.

Stainless Steel Machining Housing for Hydraulic Accessories

The processing quality is stable, the machining accuracy is high, the repetition precision is high, the processing requirement of the aircraft is suitable.

Stainless Steel Precision Casting Part for Automobile

Stainless steel precision casting is a casting process with less cutting or no cutting, is an excellent technology in foundry industry

Product Description of Customized Precision CNC Machining Part

Customized Precision CNC Car Parts1. material: carbon steel, stainless steel, alloy steel, aluminium alloy, zinc alloy etc.

2. surface treatment: sand blast, polishing, electroplating, electroless nickel plating, hot galvanizing, spray coating, dacromet etc.

3. heat treatment: quenching, annealing, tempering, normalizing etc.

4. process: die casting, investment casting, gravity casting, hot forging, maching, stamping etc.

5. packing: as customer's require

Basic Info of Customized Precision CNC Machining Part

Model NO: RL430Process: Machining

Trademark: Relong

Specification: ISO9001, TS16949

Origin: China

Production Capacity: 5000000 PCS/Year

Transport Package: Carton with Pallet or as Your Requirement

Payment Terms:T/T

General precision CNC machining usually refers to precision machining, CNC machining lathe, CNC milling machine, CNC milling machine, etc. CNC lathe feed processing route tool from the knife point movement began fixed origin (or machine), until the return to that point and end the route processing program, including cutting paths and cutting tool cut, cut out of the empty travel path.

The feed route of the finishing process is basically in the order of the contour of the parts, so the key to determine the route is to determine the route of rough machining and empty stroke.

In cnc lathe processing, the determination of machining route generally follows the following principles.

1. The precision and surface roughness of the workpiece should be guaranteed.

2. The processing route is the shortest, reducing the idle time and improving the processing efficiency.

3. To simplify the work of numerical calculation and simplify the processing procedure.

4. For certain repetitive programs, subroutines should be used.

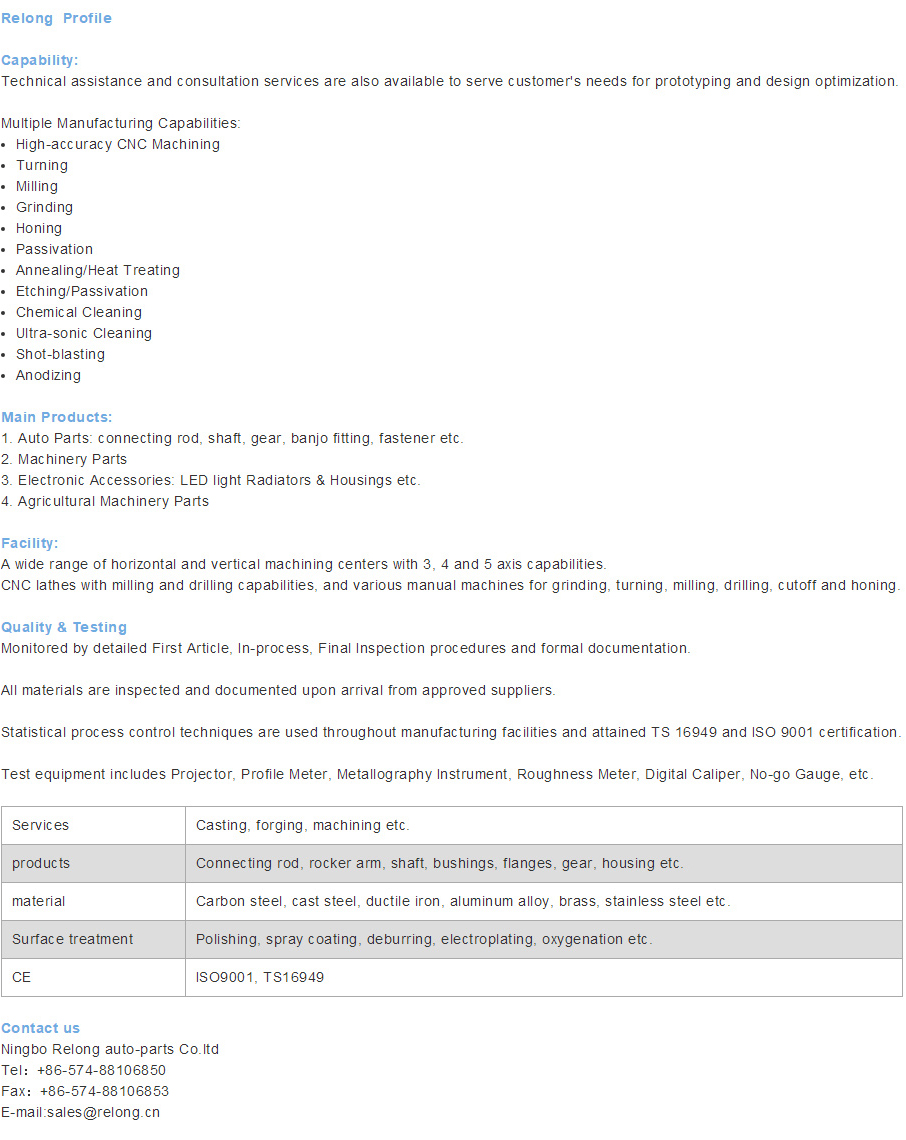

Relong CNC machining has the following advantages:

1.There is a great deal of reduction in the quantity of work load, and the complex parts do not require complicated tooling. If you want to change the shape and size of the parts, you only need to modify the parts processing program, which is suitable for the development and modification of new products.

2.The processing quality is stable, the machining accuracy is high, the repetition precision is high, the processing requirement of the aircraft is suitable.

3.The production efficiency of multi-variety and small-batch production is higher, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the optimal cutting quantity.

4.It is difficult to process the complex surface of the conventional method, and can even process some unobserved processing parts.

Leave a Message

Email Us

we will contact you within 24 hours.

- TEL:+86-0574-88106851

- FAX:+86-0574-88106851

- EMAIL:sales@relong.cn

- ADDRESS:11/F, South Building, No. 1299, East Yinxian Avenue, Ningbo, China