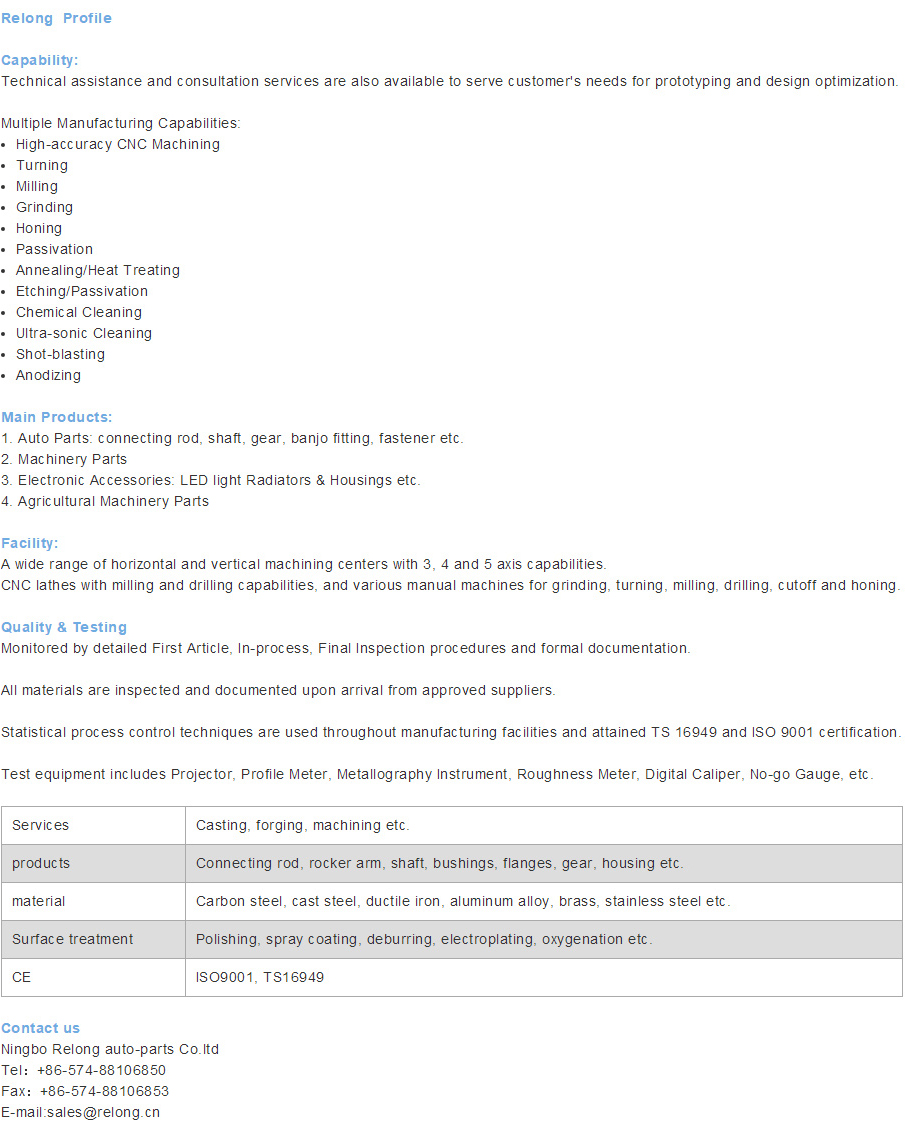

Aluminium Alloy Precision Casting for Auto Parts

Similar products

Rubber Gasket

This kind of gasket can be widely used in all kinds of mechanical equipment, such as gasket, seal, buffer, etc.

Rubber Seal

This kind of sealing ring is widely used in the automobile engine, condenser, and other precision machinery equipment.

Precision Hot Forging Flanges with Stainless Steel

The processing quality is stable, the machining accuracy is high, the repetition precision is high, the processing requirement of the aircraft is suitable.

Product Description of Aluminium Alloy Precision Casting for Auto Parts

Aluminium Alloy Precision Casting for Auto Parts (RL070)1. material: carbon steel, stainless steel, alloy steel, aluminium alloy, zinc alloy etc.

2. surface treatment: sand blast, polishing, electroplating, electroless nickel plating, hot galvanizing, spray coating, dacromet etc.

3. heat treatment: quenching, annealing, tempering, normalizing etc.

4. process: die casting, investment casting, gravity casting, hot forging, maching, stamping, alloy casting process, castalloy etc.

5. packing: as customer's require

Relong is your ideal alloy die casting company for auto parts customization.

Basic Info of Aluminium Alloy Precision Casting for Auto Parts

Model NO: RL070Material: Aluminum Alloy

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Surface Preparation: Oxygenation

Process: Die Casting

Pressure Chamber Structure: Horizontal

Machining: CNC Machining

Tolerance Grade: 6

Casting Surface Quality Level: 3

Trademark: Relong

Specification: ISO9001, TS16949

Certification: ISO 9001:2008

Origin: China

Production Capacity: 100000 PCS/Year

Transport Package: Carton with Pallet or as Your Requirement

Payment Terms:T/T

Zinc alloy die casting is made of molten metal, and the aluminum alloy of various shape parts is obtained. It has the advantages of low density, higher strength, corrosion resistance and casting process, and limited design of parts. The medium strength alloy is divided into al-si and al-si-mg-cu. High-strength alloy of al-cu; Al-mg alloy; Al-re is a hot, strong alloy of base. Most need to be heat treated to achieve the purpose of strengthening the alloy, eliminating the internal stress of the castings, stabilizing the organization and the size of the parts. Used for manufacturing girder, flame turbine blade, pump body, hanger, wheel hub, inlet lip and engine casing, etc. It is also used to manufacture the cylinder head, gearbox and piston of the automobile, the shell of instrument meter and the pump body of supercharger.

The aluminum alloy used in the required parts is obtained directly by casting process. It is required to have ideal casting properties: good fluidity, smaller shrinkage, thermal cracking and cold crack orientation, smaller segregation and inhalation. The element content of casting aluminum alloy is generally higher than that of the corresponding deformation aluminum alloy.

Casting aluminum alloy has good casting properties, which can be made into complicated parts. No bulky additional equipment is required; It has the advantages of saving metal, reducing cost and reducing working hours. It has been widely used in aviation industry and civil industry. Used for manufacturing girder, flame turbine blade, pump body, hanger, wheel hub, inlet lip and engine casing, etc. It is also used to manufacture the cylinder head, gearbox and piston of the automobile, the shell of instrument meter and the pump body of supercharger.

Leave a Message

Email Us

we will contact you within 24 hours.

- TEL:+86-0574-88106851

- FAX:+86-0574-88106851

- EMAIL:sales@relong.cnjett@relong.cn

- ADDRESS:11/F, South Building, No. 1299, East Yinxian Avenue, Ningbo, China