Market Profile and Development Trend of China's Automotive Die Casting Industry 2018

2020.03.26 I. Market Profile of Die Casting Industry(1) International market profile

In recent years, with the development of global economy, the demand for precision die-castings in many fields, such as automobile, 3C products, communication infrastructure, household appliances and medical equipment, has grown steadily.

At present, the die-casting market in developed countries is relatively mature. With the improvement of die-casting equipment and technology, more and more ferrous metal castings are replaced by non-ferrous metal die-castings such as aluminum alloy and magnesium alloy die-castings. The production and consumption of die-castings around the world are mainly concentrated in the United States, China, Italy, Germany, Mexico, Japan and other countries. For developed countries, due to their leading advantages in equipment and technology, their die-casting industries are generally dominated by high-quality and high-value-added die-casting such as automotive, communication and aviation.

There is a relatively small number of die-casting enterprises in developed countries, but a single enterprise has a large scale, high degree of specialization, and a great advantage in capital, technology and customer resources.

(2) Domestic market profile

As the downstream manufacturing industry gradually gathers in China, China's automotive die casting industry has also substantially developed with the improvement of China's overall industrialization level, and has gradually developed into a major country in the world die-casting industry. Judging from the output of die-castings, with the steady and rapid development of China's automotive, communication infrastructure, 3C products, equipment manufacturing industry, household appliances, mechanical and electrical instruments, light industry, etc., as well as the transfer of foreign die-casting industries to China, China's die-casting industry has entered a new normal with steady growth.

As more and more production capacity of high-end manufacturing industry shifts to China, China's die-casting industry keeps upgrading its structure in the process of growth, and the proportion of precision die-castings gradually rises. By the end of 2013, the proportion of die-casting products used in automotive industry in China had reached above 70%, which was basically the same as that in developed countries.

As the most important type of die-casting products, the demand for automotive parts especially automotive aluminum alloy die-castings, will greatly affect the overall development prospect of the die-casting industry. From the perspective of the whole automotive structure, a large number of precision die-castings are used in automotive engines, gearboxes, transmission systems, steering systems and electronic control systems. In addition, aluminum alloy die-castings are also used in large components such as the body frame.

II. Market Profile of automotive Die-Casting Industry

automotive industry serves as the most important application field of die-casting products. A large number of precision die-castings are used in automotive engines, gearboxes, transmission systems, steering systems and electronic control systems. The demand for automotive parts will greatly affect the overall development prospect of the die-casting industry.

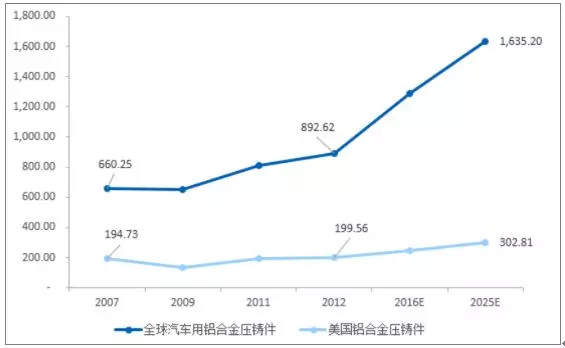

As people pay increasing attention to energy conservation and environmental protection of automotives, a trend of replacing steel and iron with aluminum over the past three decades has presented in the mobile industry, which continues now. At present, the overall trend of fast development is shown in the global market of automotive aluminum alloy die-castings. It is estimated that the global sales will reach 16.352 million tons in 2025, increased by 83.19% from 2012.

In addition to aluminum alloy die-castings, zinc alloy, magnesium alloy and copper alloy die-castings are also used in automotives. According to the statistics, the consumption of automotive die-castings in China from 2011 to 2015 is shown as follows:

The demand for aluminum, zinc and other metal die-castings in the automotive industry will keep growing in the future, which is mainly affected by the following factors:

(1) China's automotive industry will develop at a relatively fast speed

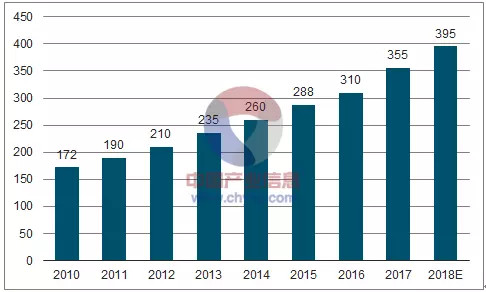

Since the reform and opening-up, with the rapid growth of China's economy, China’s automotive industry has also developed substantially. In 1980, China's automotive production reached 222,300, and it increased to 28,122 million in 2016, an increase of 125.49 times. In recent years, affected by international and domestic economic situations, the growth rate of China's automotive production has declined. But the annual new automotive production still has a considerable scale owing to its high base. China's automotive production recently is shown as follows:

In 2016, the number of China's private car ownership was 146 million, with 36 cars per 100 households, far lower than that of developed countries. Therefore, there is still a large space for development in China's automotive industry in the future.

(2) Trend of automotive lightweight

The so-called automotive lightweight means reducing curb weight as much as possible on the premise of ensuring the strength and safety of the vehicle, so as to improve dynamic property, reduce fuel consumption and reduce exhaust pollution. For vehicle lightweight, different components have different degrees of contribution. The lightweight of the car body, interior and exterior decorations and the power system is of great significance to reduce energy consumption when driving.

Aluminum alloy materials are characterized by light, recyclable and easy to shape. In theory, aluminum cars can reduce their weight by 30% to 40% compared with steel cars. Among them, aluminum engines can reduce 30% of their weight; aluminum radiators are 20% to 40% lighter than copper radiators; all-aluminum bodies reduce more than 40% of their weight compared with steel; and aluminum wheels can reduce 30% of their weight. Therefore, aluminum alloy belongs to one of the most ideal materials for automotive lightweight.

Since 2011, due to concerns on reducing greenhouse gas emissions and reducing fossil fuel dependence, the requirement for the indicators of vehicle fuel consumption has been raised; Corporate Average Fuel Economy has forced automotive manufacturers to move towards lightweight to reduce fuel consumption. As one of the key technologies of automotive energy conservation, lightweight is remarkable in its energy-saving effect. By reducing the weight of gasoline passenger vehicles by 10%, the fuel consumption can be reduced by 3.3%; and the weight loss of 15% contributes to the reduction of 5% in fuel consumption. For diesel vehicles, fuel consumption can be reduced by 3.9% and 5.9% respectively.

Lightweight is also good for electric vehicles (including plug-in hybrids) in energy-saving effect. Weight loss of 10% and 15% can consume electric energy of 6.3% and 9.5% respectively. The researchers has also conducted relevant experiments on trucks with different energy categories, which has shown good energy-saving effect as well.

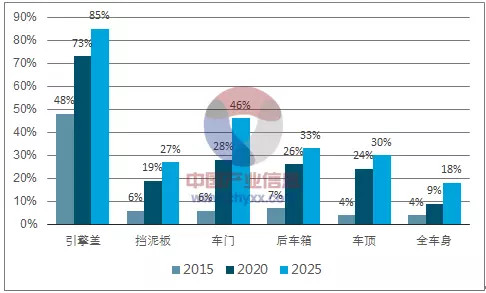

Reducing the vehicle weight is conducive to reducing the engine load, improving the driving performance and effectively reducing the braking distance, so that vehicles can be more flexible in the process of steering and passing curves, thus making them more stable. Vehicles tend to be more comfortable and safe, as the aluminum alloy structure can absorb and disperse more energy when impacted. As a result, the aluminum permeability of major parts in automobile will raise significantly in the next decade. According to the forecast, the permeability of aluminum hood will raise from 48% in 2015 to 85% in 2025, and the permeability of aluminum door from 6% in 2015 to 46% in 2025. Specifically, the average amount of aluminum used per vehicle in North America was 54kg in 1980, and it increased to 154kg in 2010. It is estimated that the average amount of aluminum used per vehicle will reach nearly 325kg by 2025.

(3) The development of new energy vehicles will further boost the demand for metal die-castings

At present, one of the main problems of new energy vehicles lies in its short range, and lightweight design has become the major measure to reduce weight and energy consumption for new energy vehicles. Take TESLA Model S as an example, its total weight is 2,108kg, while the weight of the battery alone is more than 500kg. In addition, the driving motor adds to the total weight. The total weight of a traditional car’s engine is usually 80 to 160kg. A car with 70L of petrol can drive a range of 700 to 900km, while an electric car with 500kg of battery only 400 km. Therefore, the major measure of lightweight for new energy vehicles is to increase the proportion of automotive aluminum alloy die-castings.

As China issues and implements the policy of energy conservation and emission reduction in automotives, a trend of fast development has shown in China's new energy vehicles in recent years. The total production of new energy vehicles in 2016 was 517,000, an increase of 49.99% from 2015. Among them, the production of pure electric passenger vehicles increased most significantly, an increase of 73.10% higher than that of 2015; the production of pure electric commercial vehicles increased by 50.20% compared with 2015; the production of plug-in hybrid passenger vehicles increased by 29.9% from 2015. From January to June in 2017, 212,000 new energy vehicles were produced, increased by 19.77% over the same period last year. Among them, the production of pure electric passenger vehicles increased most significantly, rose by 30.60% over the same period last year.

The requirements for body weight in new energy vehicles are more stringent than traditional energy vehicles, thus light aluminum alloy die-castings are adopted more. For instance, in TESLA Model S series, aluminum alloy materials are used in 95% of the structure. The stable and rapid growth of new energy vehicles will give a strong impetus to the development of automotive aluminum alloy die-casting industries.

Related News

Do you really know about the current situation and development trend of automotive rubber parts?

September 3, 2018The rapid development of China's automotive industry is promoting the related supporting industries, especially the rubber industry. Over the years, automotive rubber parts have developed into a uniqu... view

Anti-Vibration &Safety Product of Rubber Auto Parts

September 3, 2018Anti-vibration productIt is mainly installed in the engine, car body, air conditioning and car suspension system. It is mainly used to reduce vibration and noise when driving, improve the stability, s...view

Pressure Die Casting Parts Development Prospects

September 3, 2018China's economy is still developing rapidly. As the contradiction between the resources and the environment is increasingly intensifying, according to the requirements of Scientific Outlook on Develop...view

Automotive Window Gasket Rubber Daily Maintenance

September 3, 2018Check whether there is any big crack or fracture in the seal. If the seal is broken, it can be repaired with a binder. Using the special seal adhesive can patch up the big cracks easily. Of course, if...view

Variety of Rubber Auto Parts

September 3, 2018There are many kinds of the rubber auto parts except the tires. Generally, one car is equipped with 200 to 300 kinds of rubber auto parts, and some wagons and industrial cars can have 400 to 600 piece...view

Design Programming of Die Casting Parts

September 3, 2018Design specification for wall thickness of auto die casting partsDie casting parts with thin walls have higher strength and better compactness than the ones with thick walls. In view of this, the desi...view

- TEL:+86-0574-88106851

- FAX:+86-0574-88106851

- EMAIL:sales@relong.cnjett@relong.cn

- ADDRESS:11/F, South Building, No. 1299, East Yinxian Avenue, Ningbo, China