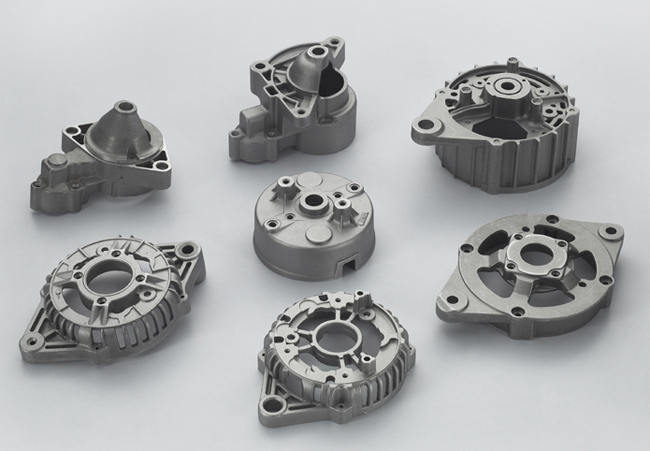

Brief Introduction of Die Casting Parts

2020.03.30Die casting parts are a kind of pressure casting part, it is produced through the process as follows: Pour the metal (such as copper, zinc, aluminum, aluminum alloy, etc.) that has been heated into liquid into the feeding inlet of the die casting machine. The die casting machine has been equipped with the casting moulds. Through the pressure casting of the die casting machine, the copper, zinc, aluminum or aluminum alloy parts with specific shapes and sizes are cast. These products are usually called die casting parts. The die casting parts have different names on different occasions, there are die casting parts, pressure castings, die castings, die casting aluminum, die casting zinc, die casting copper, copper castings, zinc castings, aluminum castings, aluminum alloy castings, aluminum alloy die casting parts, etc.

Characteristic of Die casting parts

Because the metal copper, zinc, aluminum and aluminum alloys have good fluidity and plasticity, and the process of casting is carried out in the pressure die casting machine, the aluminum die casting can be given a variety of complex shapes, high precision as well as good finish, thus greatly reducing the amount of mechanical processing and the casting allowance of copper, zinc, aluminum and aluminum alloy, which not only saves electricity and metal materials, but also greatly saves labor costs. With the characteristics of excellent thermal conductivity, small specific gravity and high machinability, copper, zinc, aluminum and aluminum alloy castings are widely used in the automobile manufacturing industry.

Do you really know about the current situation and development trend of automotive rubber parts?

September 3, 2018The rapid development of China's automotive industry is promoting the related supporting industries, especially the rubber industry. Over the years, automotive rubber parts have developed into a uniqu... view

Anti-Vibration &Safety Product of Rubber Auto Parts

September 3, 2018Anti-vibration productIt is mainly installed in the engine, car body, air conditioning and car suspension system. It is mainly used to reduce vibration and noise when driving, improve the stability, s...view

Pressure Die Casting Parts Development Prospects

September 3, 2018China's economy is still developing rapidly. As the contradiction between the resources and the environment is increasingly intensifying, according to the requirements of Scientific Outlook on Develop...view

Automotive Window Gasket Rubber Daily Maintenance

September 3, 2018Check whether there is any big crack or fracture in the seal. If the seal is broken, it can be repaired with a binder. Using the special seal adhesive can patch up the big cracks easily. Of course, if...view

Variety of Rubber Auto Parts

September 3, 2018There are many kinds of the rubber auto parts except the tires. Generally, one car is equipped with 200 to 300 kinds of rubber auto parts, and some wagons and industrial cars can have 400 to 600 piece...view

Design Programming of Die Casting Parts

September 3, 2018Design specification for wall thickness of auto die casting partsDie casting parts with thin walls have higher strength and better compactness than the ones with thick walls. In view of this, the desi...view

- TEL:+86-0574-88106851

- FAX:+86-0574-88106851

- EMAIL:sales@relong.cnjett@relong.cn

- ADDRESS:11/F, South Building, No. 1299, East Yinxian Avenue, Ningbo, China